Introduction

Homogenization- Milk is an oil-in-water emulsion. Fat globules in the milk are dispersed in a continuous water phase (skim milk) and normally vary in sizes ranging from 1 mm to 22 mm,with a mean size of approximately 3-4 mm.

As the density of milk fat is less than that of skim milk, the fat globules tend to rise to the surface during storage and form a cream layer. The rise of fat globules follows Stoke’s law where the velocity of rising fat globules is expressed as:

V a(d2 (rs – rf))/18h

Where, d = diameter of the fat globule, rs = density of the serum phase, rf = density of milk fat and n = viscosity of milk serum.Homogenization

Very small fat globules (<1 mm) remain suspended in the serum phase due to brownian motion and adversely affect the creaming phenomenon. The presence of cryoglobulins in the raw milk causes agglomeration of fat globules, which subsequently have increased tendency to rise to the surface.

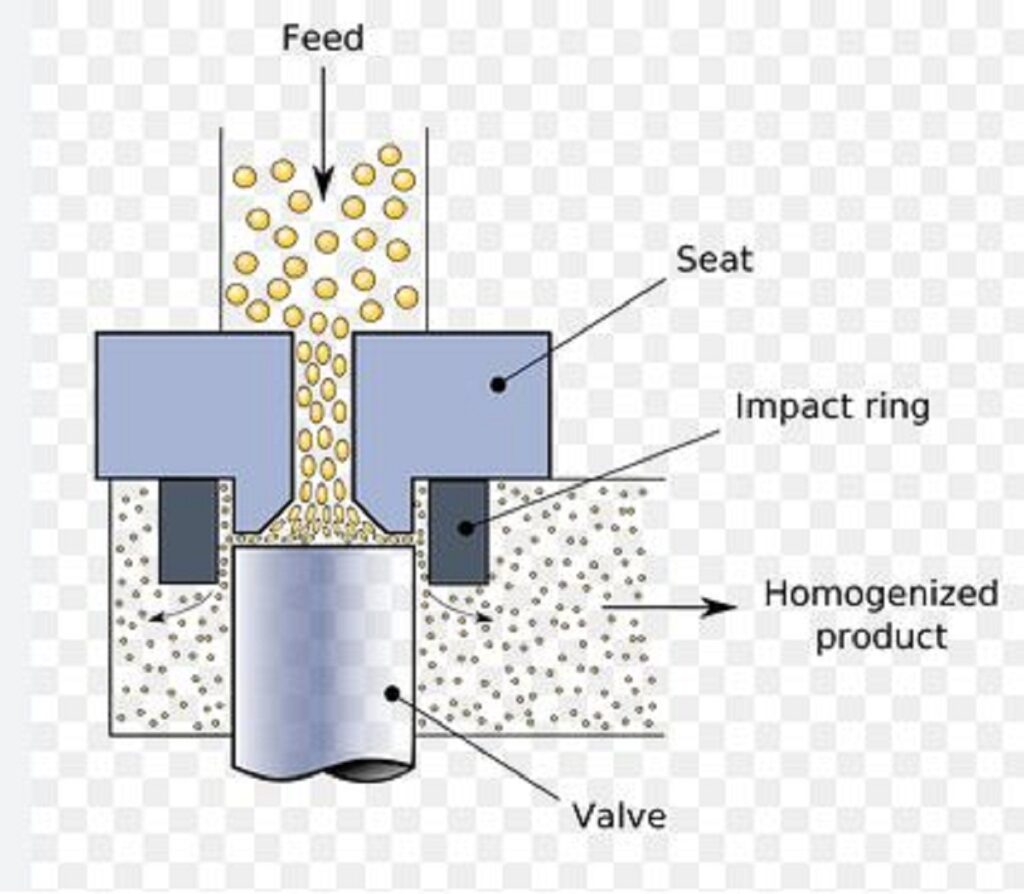

Homogenization is a mechanical process in which milk is forced through a homogenization valve under very high pressure. The milk is thus deflected at right angles through a narrow opening of about 0.1 nm (100mm). As the milk comes out of this valve opening, there is sudden drop in pressure and the milk is subjected to impact against an impact ring.

This complete process results in disruption of fat globules leading to decrease in the average diameter (typically from 0.2 to 2 mm) and an increase in the number and surface area of fat globules.

Homogenization with reference to milk/ dairy applications thus refers to a mechanical process that is used to reduce the size of fat globules such that milk fat does not rise to form a cream layer during storage of milk. Although homogenization renders fat globules uniformly distributed in the body of the milk, upon prolonged storage it does not remain completely dispersed.

Definition of Homogenized Milk

United State Public Health Service has proposed one of the most comprehensive definitions for homogenized milk. This has been the most widely accepted and referred definition.

It states that “Homogenized milk is milk which has been treated in such manner as to ensure break-up of the fat globules to such an extent that after 48 hours of quiescent storage no visible cream separation occurs in the milk and the fat percentage of the milk in the top 100 ml of milk in a quart bottle (946ml),or of the proportionate volumes in containers of other sizes, does not differ by more than 10 per cent of itself from the fat percentage of the remaining milk as determined after thorough mixing.

Theories of Homogenization

The principle underlying the process of homogenization is to subject the fat globule to enough severe conditions, which disrupts it into smaller globules. The newly formed fat globules are maintained in dispersion for sufficient time to allow milk fat globule membrane (MFGM) to be formed at the fat-serum interface. The following theories have been proposed to be responsible for the entire phenomenon.

Shearing or Grinding:

As milk is passed at high pressure (velocity ~ 200-300 m s-1) through the homogenizer valve (~ 100 mm gap), fat globules undergo shearing action. The shear between fat globules and the surface of the homogenizer wall coupled with wire drawing effect results in elongation of the fat globules which progressively becomes unstable.

These phenomenon result in subdivision of the fat globules. Furthermore, the difference in velocity of the faster moving serum phase at the centre of the liquid stream as compared to the liquid near the edge of the stream causes the fat globules to grind against each other. The turbulence created by the difference in velocity and eddy currents of the liquid add to the shear effects and thus enhance the process of disruption of the fat globules.

Exploding:

This theory suggests that during homogenization, there is build up of tremendous pressure. When this pressure is suddenly released, the internal pressures within the fat globules pull the globule apart with exploding effect. This results in disintegration or subdivision of fat globules into smaller globules.

Splashing/Shattering:

As the high homogenizing pressure is attained in the homogenizer, the homogenizing valve releases the highly compressed milk at very high velocity. The liquid suddenly strikes a retaining wall/ perpendicular surface.This causes splashing or shattering effect on the fat globules resulting in break down of globules into smaller sizes.

Acceleration and Deceleration:

This theory relates sudden change in velocity of milk as it passes through homogenizer to the homogenization effect. When milk enters the homogenizer valve, velocity of milk changes from almost static to very high velocity. As it comes out of the valve, there is sudden deceleration at a rate at which it was accelerated. This sudden change in velocity results in shattering effect leading to division of fat globules.

Cavitation:

It is postulated that as the milk passes through the homogenization valve, the initial homogenization pressure decreases sharply due to sudden increase in the velocity of milk. Depending on the back pressure that exists outside the homogenizer valve, the pressure can drop to as low as the saturated vapour pressure of liquid. This leads to formation of vapour bubbles due to cavitation. Cavitation generates shock waves, which could be in excess of 1600 kg/cm2 in intensity. Due to overlapping of these shock waves, disintegration of the fat globules may occur.

For more on this pl do visit Dairyheaven