Here we are going to discuss on Nanofiltration and its 7 Amazing Application in Dairy Industry

Introduction

Membrane technologies started to enter in an industrial reality with the pioneering work of Loeb and Sourirajan (1963)

He developed the first anisotropic membranes, made from cellulose acetate, able to deliver reasonable fluxes and permeabilities for sea water desalination by reverse osmosis.

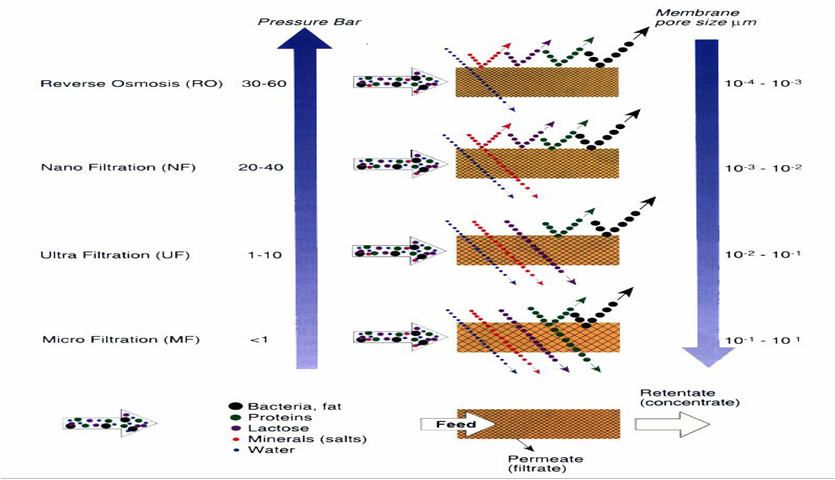

Among the food industries, dairy has undoubtedly known the largest introduction of most of the membrane technologies MF, UF, NF, and RO.

What is Nanofiltration?

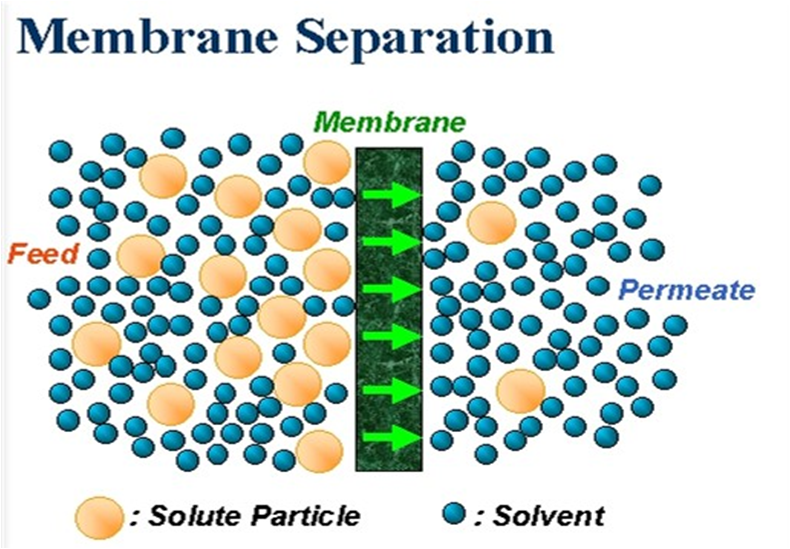

•A pressure-driven membrane separation process using porous charged membranes with average pore size diameter under 0.001 mm (1 nm).

•NF retains lactose and all other larger milk components but allows permeation of monovalent soluble mineral ions and water.

•A complementary process to reverse osmosis.

•Loose RO (There is an osmotic pressure developed but it is less than that of the RO process).

•Where divalent cations and anions are preferentially rejected over the monovalent cations and anions.

•Water and substances with a molecular weight < 200 D are able to permeate the semipermeable separation layer.

Filter Materials

•Cellulose for the base material

•Alumina powder with glass fibers bonded at 100°C

•Polyvinyl-alcohol

•Polyvinylidene Chloride

•Polyvinylidene Fluoride

•Polyvinylidene Halide

•Melamine-formaldehyde as resin

•Modified Polyamide,

•Polyamide hydrazide,

•Sulphonated polysulphone, etc.

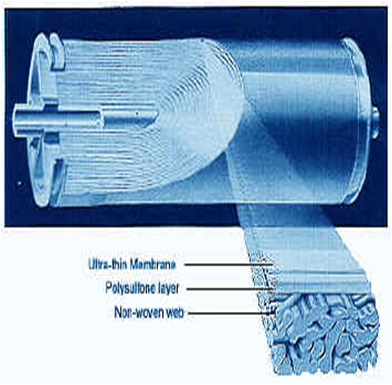

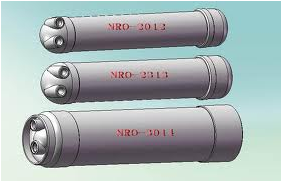

Fabrication of Filters

•The base material is made from a web of cellulose .

•The cellulose web has the ability to retain a rigid shape.

•The nanofibers are then applied be electrospinning to the cellulose layers.

•Resin is applied, most likely immediately before the nanofiber material.

•Forming various layers of nanofibers, cellulose and

•other materials result in a stepped filtration device.

Nanofiltration and its 7 Amazing Application in Dairy Industry

Application of NF for the Production of Milk product

•For fermented milks such as yogurts, enrichment of milk by NF has led to products considered as better in terms of texture and flavor than those made from milk added with milk powder (Tamime and Robinson, 1985).

•Such results probably originated by a drastic reduction of the Maillard reaction always initiated in milk powders and the absence of insoluble particles that are more or less present in even high-quality powders.

•The specific increased flavor improvement found in yogurts made from milk concentrated by NF likely originates from the specific decrease in monovalent ions (Na and Cl) to which consumers are particularly sensible

Application s of NF for the Treatment of Whey

•Whey processing was one of the first applications of membrane technologies in the dairy industry.

•Use of RO instead of vacuum evaporation for pre-concentration of whey has allowed for a large saving in energy.

•A large part of the RO membrane area carrying out this concentration on sweet whey is replaced by NF membrane in order to simultaneously perform concentration and partial demineralization.

•Moreover, this double effect obtained by the use of Nanofiltration leads to a saving of energy compared to RO.

•NF performs simultaneously separation of salts (mainly monovalent species Na, K, H+, and Cl) and concentration.

•In lactose production, Nanofiltration is the best solution to convert acid and salty whey to normal whey and consequently solve a disposable environmental problem .

•Spray-drying of acid whey treated by NF showed a significant improvement in running parameters and a three times reduction in the hygroscopicity of the powder.

•Acid whey was demineralised to a degree of 40% by NF and 60% by diafiltration (DF).

•The obtained deacidification levels were 30% for NF and 44% for DF.

•Comparison of obtained ash and lactic acid reductions showed that acid whey should be neutralised after NF.

•The produced purified acid whey concentrate can be used as an ingredient of food products such ice cream, yoghurt or sweet syrup.

Composition of the different products achieved by Nanofiltration of acid whey

| Raw whey | Concentrated whey | Permeate | Losses | |

| Total solids | 6.5 % | 18.5 % | 0.37 % | |

| Total protein [% TS] | 12.8 | 13.5 | 0 | 0 |

| NPN [% TS] | 0.5 | 0.36 | 4.32 | 31% |

| Lactose [% TS] | 74.4 | 77.0 | 26.2 | 1.3% |

| Organic acids [% TS] | 3.4 | 3.37 | 4.9 | 5% |

| Ashes [% TS] | 7.7 | 5.3 | 68.8 | 28% |

| Fat [% TS] | 0.7 | 0.8 | 0 | 0 |

The composition of the ashes of the raw whey and the concentrated whey shows the preferential transport of monovalent ions through the Nanofiltration membranes

| Raw whey | Concentrated whey | Permeate | Losses | |

| Ca [%TS] | 0.42 | 0.41 | 0.7 | 6% |

| Mg [%TS] | 0.12 | 0.12 | 0.21 | 6% |

| Na [%TS] | 0.61 | 0.38 | 6.5 | 40% |

| K [%TS] | 2.36 | 1.48 | 25.2 | 40% |

| S [%TS] | 0.16 | 0.15 | 0.55 | 12% |

| P [%TS] | 0.62 | 0.57 | 2.05 | 12% |

| Cl [%TS] | 1.44 | 0.68 | 21.1 | 54% |

Applications of Nanofiltration for the Treatment of Brine and Dairy Waste waters

•The first industrial applications concerned the milk components contained in “white waters” resulting from the condensation of milk water during vacuum evaporation of milk.

•which are now treated either by RO or by a NF + RO (named polishing step) in order to reduce their volume at least 20 times.

A two-stage ultrafiltration and Nanofiltration (UF/NF)

•For the treatment of model dairy wastewater.

•Ultracel PLGC and NF270 membranes were found to be the most suitable for this purpose.

•1st – protein and lipid were concentrated by the Ultracel PLGC UF membrane and could be used for algae cultivation to produce biodiesel and biofuel. 2nd- the permeate from UF was concentrated by the NF270 membrane in the second stage to obtain lactose in retentate and reusable water in permeate, while the NF retentate could be recycled for anaerobic digestion to produce biogas

•NF for peptide fractionation in model mixtures of amino acids and peptides .

•Nanofiltration has also been used to fractionate complex protein hydrolysates that contain bioactive peptides.

•In combination of UF and NF it was possible to separate and isolate a peptide fraction with peptides having a molar mass range of 500-1800 Da.

Some other application

•The Nanofiltration combine with bipolar electrodialysis in downstream purification can replace the multiple purification steps by two steps while yielding a monomer grade lactic acid from a mixture of unconverted sugars and lactic acid.

•Nanofiltration for the Recovery of Caustic Cleaning-in-place Solutions.

•Good recovery of caustic solutions, even when faced with large variations of solutions composition.

•High caustic yield, permeation flux in the range 42–110 l /h, average chemical oxygen demand (COD) reduction equal to 0.58 to 0.2-o.3g/l.

Summury and conclusion

Nanofiltration is a very effective process and has very amazing application in dairy industry,

For more such containt do visit our website Dairyheaven