Introduction

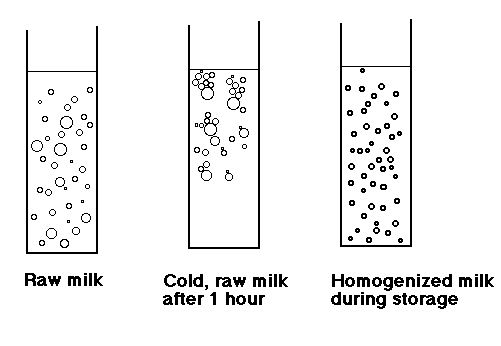

As per the United State Public Health Service, “Homogenized milk is milk which has been treated in such manner as to ensure break-up of the fat globules to such an extent that after 48 hours of quiescent storage, no visible cream separation occurs in the milk and the fat percentage of the milk in the top 100 ml of milk in aquart bottle (946ml),or of the proportionate volumes in containers of other sizes, does not differ by more than 10 per cent of itself from the fat percentage of the remaining milk as determined after thorough mixing.

In This article we will focusing on Advantages and Disadvantages of Homogenized milk

Advantages of Homogenized milk

- Prevents removal of fat/cream from milk

- Homogenized milk results in softer curd and therefore easily digested by infants

- Churning of fat does not occur during bulk transportation

- Fat is uniformly distributed and therefore gives uniform consistency

- Homogenized milk is comparatively resistant to development of oxidized flavour defect

Disadvantages

- Homogenization offers possibility of incorporation of foreign fat into milk

- Homogenized milk is prone to development of ‘sunlight’ or ‘activated’ flavour defect

- Homogenized milk if returned unsold from the market is difficult to salvage as centrifugal separation of fat is not possible

iv. Viscolised Milk

Viscolised milk refers to a product, which has unusually deep cream/fat layer resulting from admixing of homogenized cream, skim milk and/or whole milk.

The homogenized fat forms very loose clumps with the unhomogenized fat globules and rise to the surface giving an appearance of deep cream layer.

The unfair traders who first separate the cream, homogenize it and then remix with the skim milk sometimes practice it. This gives the remixed milk a very rich and creamy surface appearance and thus deceives the consumers.

v. Design and Operation of Homogenizers

There are several types of homogenizer valves and therefore designs of homogenizers vary depending on the manufacturers. However, many homogenizers used in the dairy industry have been developed based on the principles introduced by Gaulin .

Homogenizers essentially consist of two components – a piston pump to generate high pressure and a homogenizing valve. The homogenizer pump is generally a positive displacement pump with at least three and sometimes five or seven pistons, which operate consecutively to generate steady pressure.

Single piston pumps generate pulsating output with fluctuating pressure thereby resulting in poor homogenization. The pump block is generally made of stainless steel but the piston seal rings are of a soft composite material.

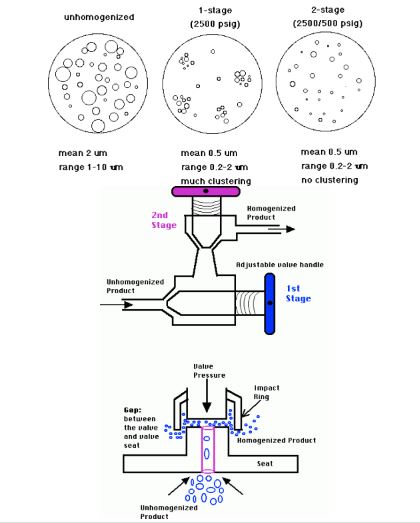

Homogenizer valves, used for milk may be either a ‘poppet type’ or ‘ball type’. A poppet design has relatively large contact surfaces and provides close fitting seal.

If maintained properly, ‘poppet’ valves give better performance with low viscosity liquids like milk. ‘Ball’ valves can exert greater pressure on the much small seal area and are therefore, suitable for high viscosity liquids or suspensions with smaller particles.

Milk from high pressure manifold enters into the centre of the valve seat. The internal diameter of the valve seat is smaller than the manifold. As it passes into the narrow gap between the fixed and the adjustable faces of this valve, milk velocity gets accelerated.

The gap is maintained against the feed pressure by a counter force exerted by an adjustable heavy duty spring. Shear effects result from the high velocity gradients between the liquid and the surface of the homogenizing valve.

Turbulence also results from the high velocity of the liquid in the valve,causing eddy currents within the flow. Liquid which passes across the valve at about 200-300 m s-1 suddenly drops in pressure to below saturation vapour pressure.

This permits microscopic bubbles to form for a few microseconds before collapsing.The high velocity jet of milk then impinges on a perpendicular impact ring. These effects contribute to the disruption of the fat globules.

Homogenizer valves are made of very tough corrosion resisting alloys such as stellite. Better resistance to corrosion can be achieved by using tungsten carbide and ceramic valves, which are used by many manufacturers in modern homogenizers.

As the fat globules are subdivided into smaller globules, there is increased surface area of the newly homogenized fat globules.

The original milk fat globule membrane(MFGM) material is not sufficient to cover this. Proteins, particularly casein micelles migrate from serum phase to form new membrane material with the existing MFGM.

This may result in sharing of the casein micelles and therefore some aggregation of fat globules could take place thus defeating the purpose of homogenization.

A second stage homogenization therefore, becomes essential at reduced pressure(almost 20% of the first stage pressure (175 kg/cm2) or upto 35 kg/cm2). This enables aggregated fat globules to be disrupted for formation of stable emulsion of finely dispersed fat globules.

vi. High Pressure Homogenization Technology

With significant improvement in understanding of machine design, material strength and fluid mechanical knowledge, homogenizers with higher pressure capabilities have been developed.

Such high pressure homogenizers could be operating based on two principles: (1) Conventional valve type homogenizer operating at a far higher pressure; (ii) Micro-fluidization based on the principle of collisions between high speed liquid jets.

Conventional Valve Type High Pressure Homogenizers (HPH):

Such high pressure homogenizers work on the principle of conventional ball-and-seat type homogenizer valve. Highly abrasive resistant and durable components of high pressure homogenizers are made from best quality stainless steel, high alloy compositions and new ceramic materials.

This allows these systems to operate at pressures upto 2550 kg/cm2 or more. Besides the regular use in emulsion formation, these high pressure homogenizers find applications in inactivation of enzymes and bacteriophages and also in destruction of micro-organisms.

Destruction of bacterial cells by HPH is due to several physical phenomenon viz., pressure drop, cavitation, shearing, turbulence and collision. These systems can be therefore, used as a combined process for pasteurization and homogenization.

Microfluidization Technology:

The microfluidizer operates under a different principle as in this case the liquid being processed is divided into micro streams that are so projected that these collide with each other.

The essential design features of micro-fluidizers include a double acting intensifier pump and an interaction chamber. The intensifier pump, which is either air-driven or electric-hydraulic driven, forces milk/product at high pressure through the interaction chamber.

The interaction chamber has fixed-geometry micro-channels, which divides the product into streams.

These streams, which accelerate to a very high velocity, are made to collide against each other. Shear and impact that occur lead to homogenization effect.

These micro-fluidizers are capable of generating pressures up to 2800kg/cm2. As in case of conventional valve homogenizers, microfluidizers too bring about changes in the fat and protein fractions of milk thereby altering some physico-chemical properties of milk.

vii. Vacuum Homogenization

This innovation in the homogenization technology is based on the discrete pulse energy input theory.

In vacuum homogenization, energy is introduced discretely into the liquid (milk) through powerful short-time impulses.

The homogenizer unit, placed in the HTST pasteurization line has two condensing chambers. The chilled milk is first pumped to condenser-I where it is heated to 20 deg. cel. and subsequently to 30deg. cel. in condenser-II. Milk then enters regeneration section of the pasteurizer where it is heated to 65deg. cel..

It is then delivered to 1st stage vacuum (homogenization) chamber through a special nozzle. As a result of flashing effect, bubbles are formed in the milk as it falls in the vacuum chamber maintained at 0.15 to 0.2 kg/cm2.

Due to the pressure changes taking place, the bubbles either show high frequency pulsation and release energy or collapse producing shockwave effect in the product. The bubbles therefore burst into smaller units and the fat globules are divided into smaller globules.

As the milk enters 2nd stage homogenization chamber, further breakdown of fat globules takes place. The outgoing milk passes through regeneration section followed by chilling section to finally attain 5deg. cel. temperature.

Besides the generally accepted homogenization effect, the other major advantages offered by this vacuum homogenizer are deodorization, reduced acidity and partial suppression of microbial activity. These systems also claim to be economical as it consumes almost 2.5 times less power than the valve type high pressure homogenizer.

viii. Checking the Efficiency of Homogenization

The method recommended by the United States Public Health Service has been the most widely used for checking the homogenization efficiency. It is performed by subjecting a specified volume (one quart) of milk to quiescent storage for 48 hours and then testing the fat in upper 100 ml and the remainder of milk. For properly homogenized milk, the percent difference in both the top 100 ml and the remainder milk should not be more than 10 per cent.